Casing and Cement QC for Plug and Abandonment

Plug and Abandonment is the final step in the lifecycle of an oil or gas well. By plugging the borehole with cement a permanent isolation of the reservoir from any other formations, in particular the groundwater and the surface is ensured. The top sections of casing are removed near the surface as well ad the pumps and installations on the surface. Finally the concrete well pad is cleared and the surface area is recultivated.

However, before this the current state of the borehole needs to be assessed. This is particularly important as some wells have been in production for decades and old documentation might be incomplete. Also, regulatory bodies can require such casing an cement assessements in order to specify certain actions for a safe P&A.

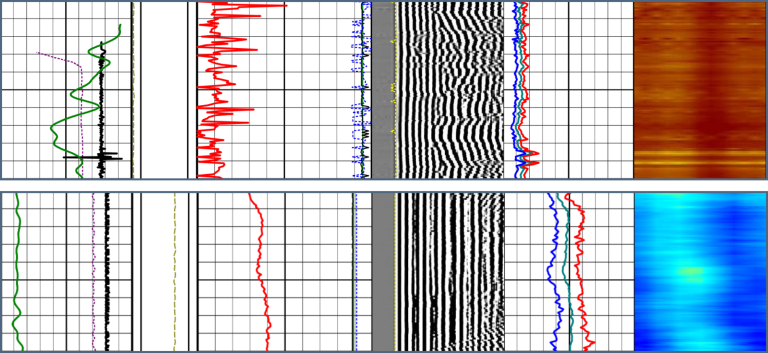

Usually, the status of casing and cement is detetermined by Cement Bond Logs, i.e. VDL and / or ultrasonic tools.

At NiMBUC, we can evaluate such investigations and make statements about the status of the borehole so that appropriate measures can be taken to safely seal the borehole.

Project facts

- Assist client with P&A operations in various fields in Germay

- Perform QC within 12 hours to ensure smooth operations without delays due to casing and cement assessement. A two-day heads-up notice by the client guarantees, that we can assign the necessary resources

- Data include well sketches, VDL and Ultrasonic data

- Depending on the complexity and the desired level of detail, we perform raw data processing and interpretation of data ourselves or work with the loggers' field prints

- First, the data quality is checked to assure the data are good to provide the needed answers

- Second, the data is evaluated to assess the presence of cement, the quality of the cement bond and the casing

- The results are compiled in a comprehensive report, highlithing the important aspects for the operator, the field crew and the regulatory bodies